General Fine-tuning the flavor of Tetraselmis chuii by modifying nitrogen supply

The nitrogen supply in the cultivation medium strongly impacts the flavor properties of the Tetraselmis chuii biomass which will have important implications for its palatability and consumer acceptance.

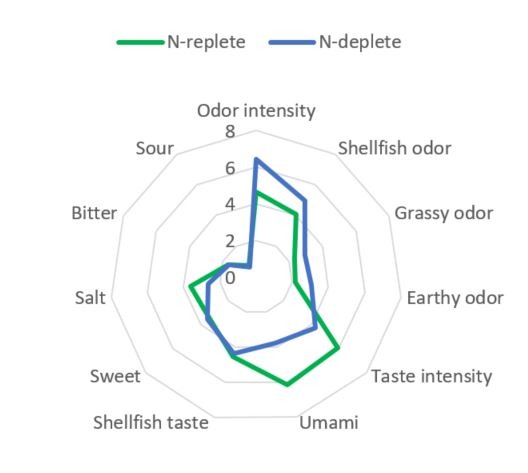

Despite the dominant shellfish-like aroma of the T. chuii biomass obtained from nitrogen starved cultivation conditions (N-deplete), some of its flavor features may be undesirable when using this biomass as flavoring. The N-deplete biomass possesses a stronger odor intensity compared to the T. chuii biomass obtained from nitrogen sufficient cultivation conditions (N-replete) due to the increased formation of odor-active VOCs 2,3-butanedione, DMS and 3-methylbutanol. Furthermore, the higher amount of odor-active VOCs 3-methylbutanal, 3-methylbutanol and 2,3-butanedione in the N-deplete biomass cause an earthy-like odor which can be perceived as an off-flavor. In addition, due to the lower amount of free amino acids and 5’nucleotides, the taste of this biomass is more flat compared to the N-replete biomass. These results indicate that the N-deplete biomass is less suitable as flavoring agents for plant-based seafood alternatives.

Nitrogen sufficient cultivation conditions positively influence the flavor properties of the T. chuii biomass. The N-replete T. chuii biomass is characterized by a stronger umami and salty taste compared to the N-deplete T. chuii biomass which is attributed to increased concentrations of free amino acid Glu and 5’-nucleotides AMP. These taste features in combination with its shellfish-like flavor provided by the presence of aroma-active sulfur-containing volatiles DMS and DMDS and nitrogen-containing volatile TMA, gives this T. chuii biomass high potential as flavoring agent for plant-based seafood alternatives.

Further flavor optimization of T. chuii might be possible as growth phase and other cultivation parameters such as light intensity and salt concentration might influence the flavor properties. Furthermore, to reduce possible off-flavors, food processors should be aware of the effect of post-harvesting conditions such as storage and drying on the flavor of microalgae biomass. Finally, the behavior and stability of the microalgae flavor during processing of the final food product should also be investigated. Our approach of modifying the cultivation conditions contributes to the improvement of the consumer acceptance of microalgae biomass and might help in the development of plant-based seafood alternatives.